Everything About Oil Field Equipment and Pipeline Equipment: Secret Insights and Essential Details

Oil field equipment and pipeline systems play a pivotal role in the oil and gas industry. They are necessary for the effective removal and transport of hydrocarbons. Trick components, such as piercing rigs and storage containers, straight effect functional success. Improvements in technology promise to improve safety and security and effectiveness. Recognizing these aspects is essential for any person entailed in or interested in this complex market, as it sets the stage for deeper exploration of market methods.

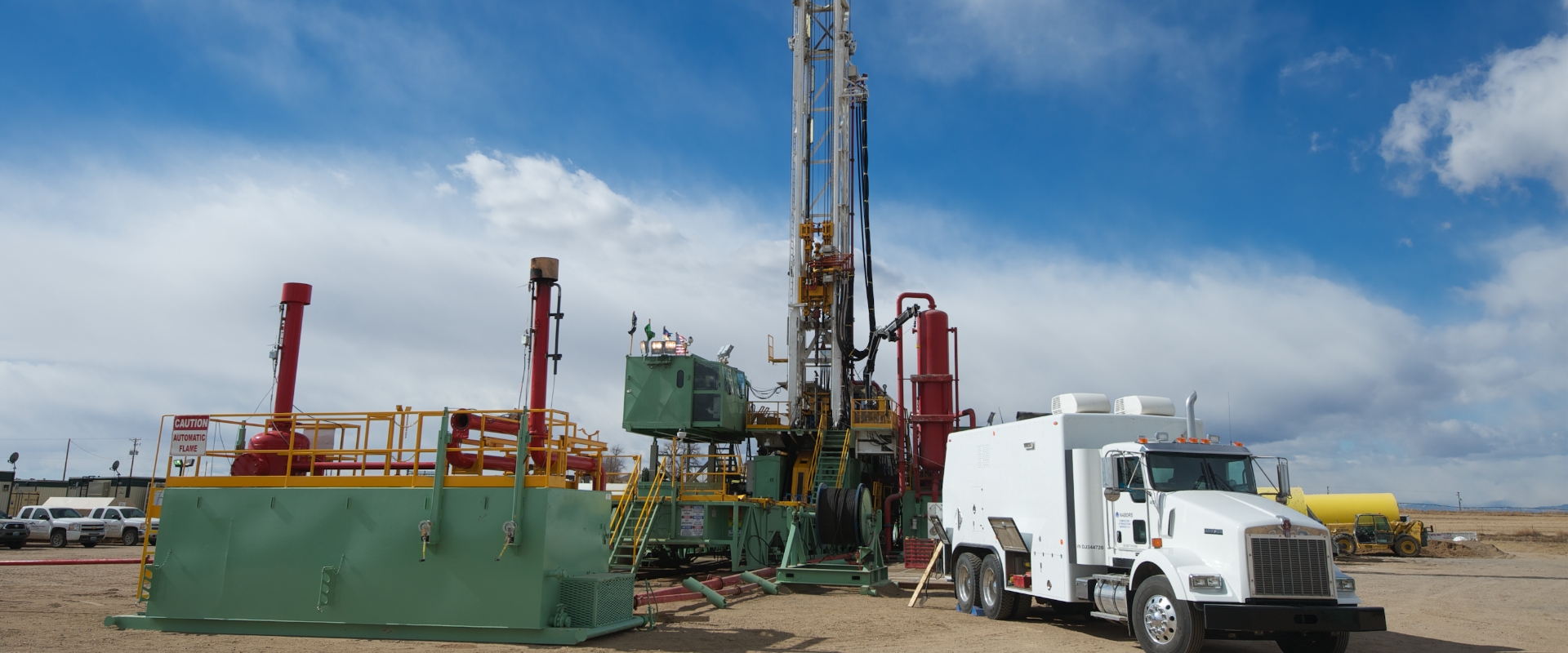

Overview of Oil Field Equipment

As the demand for oil continues to grow, comprehending the equipment made use of in oil areas comes to be significantly vital. Oil field equipment incorporates a wide variety of machinery and tools important for expedition, extraction, and processing. Trick parts consist of piercing rigs, which are vital for getting to oil tanks, and production tools, such as separators and pumps, that help with the removal process. Superior Rentals reviews. In addition, tank play a substantial role in holding petroleum prior to transportation. Security equipment, including blowout preventers and pressure gauges, guarantees operational security and effectiveness. Each tool functions cohesively to optimize manufacturing and maintain effective process. Familiarity with this tools is crucial for specialists in the industry to guarantee successful procedures and adherence to security criteria

Kinds of Drilling Rigs and Their Applications

Drilling rigs act as the backbone of oil removal operations, with various types designed for specific geological problems and functional needs. One of the most typical types consist of rotating drilling rigs, which utilize a turning drill little bit to permeate the planet, and wire tool rigs, understood for their percussion exploration approach. For overseas operations, jack-up rigs and semi-submersible rigs provide security and support in marine atmospheres. Furthermore, directional boring rigs enable operators to pierce at angles, reaching down payments that are not up and down obtainable. Each gear type has unique benefits, maximizing efficiency and safety based upon the exploration environment. Choosing the suitable gear is essential for making the most of source removal while lessening ecological impact and functional prices.

Crucial Pipeline Equipment and Their Functions

Pipeline framework is crucial for the transportation of oil and gas from removal sites to refining facilities and end-users. Different necessary devices elements facilitate this procedure. Pipelines themselves function as the key channels, useful link designed to stand up to high stress and harsh materials. Pump stations are critical for maintaining circulation by boosting pressure along the pipeline. Shutoffs play a vital role in controlling circulation and separating areas for upkeep. In addition, installations and adapters guarantee safe and secure joints in between pipeline areas. Checking systems, consisting of flow meters and stress sensing units, are crucial for finding leaks and optimizing flow rates. Lastly, pigging equipment is utilized for maintenance and cleansing, securing pipeline stability and performance. With each other, these components more information form the backbone of a reliable pipeline system.

Innovations and Technologies in Oil and Gas Equipment

Safety and Upkeep Practices in the Oil Industry

While the oil sector has made substantial strides in modern technology and effectiveness, the importance investigate this site of durable safety and maintenance methods can not be overemphasized. Reliable safety methods are vital to protect workers and the atmosphere, minimizing the risk of crashes and spills. Normal evaluations and maintenance of tools aid recognize possible issues prior to they intensify, guaranteeing functional stability. Educating programs for workers are crucial, stressing the importance of safety and security awareness and emergency action treatments. Furthermore, adherence to sector regulations and requirements cultivates a culture of safety and security. Executing sophisticated tracking modern technologies can better enhance upkeep methods, permitting for real-time assessments of equipment conditions. Inevitably, prioritizing safety and maintenance is essential to the sustainability and success of the oil market.

Regularly Asked Inquiries

What Are the Environmental Effects of Oil Field Equipment?

The environmental effects of oil field equipment consist of environment damage, water contamination, and air pollution (Superior rentals squeeze tools). Furthermore, equipment breakdown can result in spills, adversely affecting wildlife and environments, highlighting the need for rigorous regulations and monitoring

How Is Oil Field Equipment Moved to Remote Locations?

Carrying oil field equipment to remote areas often involves specific vehicles, helicopters, or barges. Logistics companies coordinate routes, making sure equipment arrives securely and efficiently, considering surface and accessibility to reduce delays and make best use of performance.

What Governing Requirements Govern Oil Field Equipment?

Regulatory criteria governing oil field equipment primarily include security, environmental security, and functional effectiveness standards. Agencies such as OSHA and EPA apply these guidelines to ensure secure methods and minimize ecological impact in oil removal procedures.

What Abilities Are Needed to Run Oil Area Equipment?

Just How Do Oil Costs Influence Equipment Demand and Usage?

Oil costs significantly influence tools need and usage. Greater prices generally result in enhanced expedition and production tasks, driving demand for machinery. Alternatively, lower costs might cause decreased procedures and decreased requirement for tools.